Moulding Industry

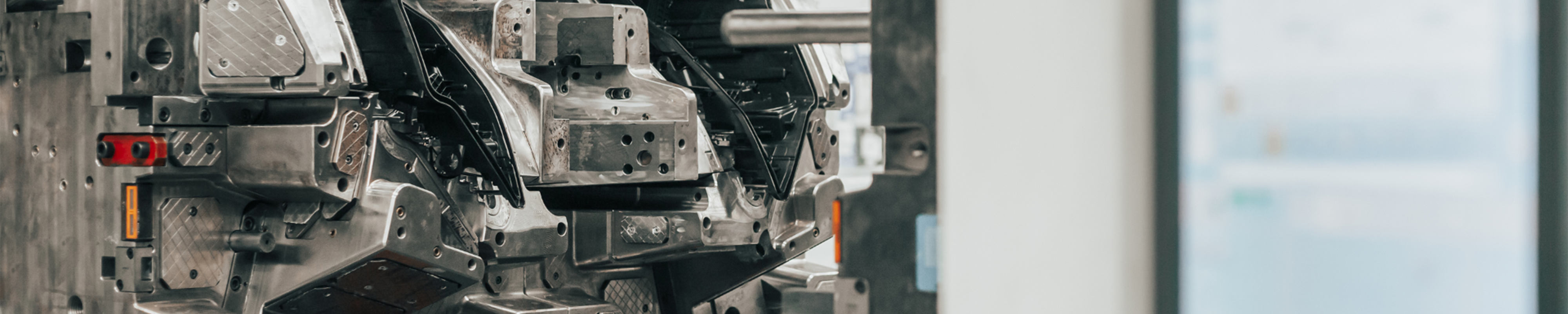

The term "moulding industry" generally refers to the sector of manufacturing that involves the process of moulding or shaping raw materials into a desired form. This industry plays a crucial role in producing a wide range of products that we use in our daily lives. There are various types of moulding processes, and each has its own specific applications.

![]()

![]()

![]()

![]()

![]()

Why trust in pewag solutions?

- Made in Europe. Designed and manufactured in Europe

- Durability and longevity. High quality materials

- Reduced risk. Hydrogen embrittlement and corrosion

- Innovative manufacturing processes. Sandblasting and galvanizing

- Extended product life. Reduced maintenance in challenging environmental conditions

- Safety. Compliance with all safety-critical specifications

Here are some key aspects of the moulding industry:

Injection Moulding

This is one of the most common processes where molten material is injected into a mould cavity. Once it cools and solidifies, the moulded part is ejected. This process is widely used for producing products, including toys, automotive parts, and household items.

Applications:

The moulding industry has diverse applications across various sectors, including automotive, aerospace, consumer goods, medical devices, and more.It produces a wide range of products such as car parts, packaging materials, medical devices, toys, and household items.

The moulding industry relies on moulds or dies, which are precision tools that define the shape and features of the final product. Specialized machines are used for different moulding processes, and they range from small, manual machines to large, automated systems. The moulding industry continues to evolve with advancements in materials, technologies, and automation, contributing significantly to the manufacturing sector.

Every mould needs a lifting point to be lifted and moved!

Lifting points and chain slings are mainly used for lifting and cleaning the moulds. Therefore, lifting points that can be rotated under load (such as the pewag PLDW and PLOW) are often used in this industry.

Learn more about moulding solutions in our pewag academy course.